ABOUT B&R AUTOMATION

Perfection in Automation has inspired and guided B&R for over 40 years.

TRENDSETTING INNOVATIONS

Perfection in Automation also means putting knowledge and creativity into developing products that become trendsetting innovations. At B&R, this means offering customers a complete automation solution that provides maximum flexibility and economic efficiency.

prototype to production

All components are developed and manufactured at their headquarters in Eggelsberg, Austria. Advanced production methods and fully automatic test procedures that use the latest technology ensure our high quality standards.

Fully Authorized B&R Integrator

Axccellus provides comprehensive electrical and mechanical engineering services in conjunction with industry leading B&R Automation software developers, to deliver the highest performing solutions available on the market today.

Process automation

Robotic integration

Material handling

Assembly automation

System integration

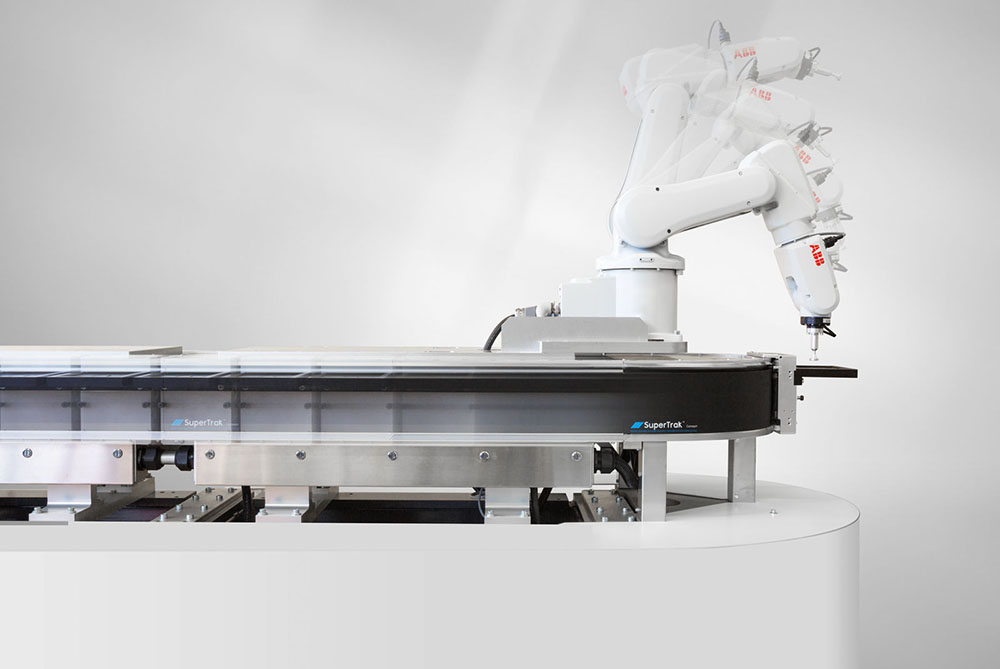

SuperTrak Transport System

B&R’s track-based transport systems let you move products through your production line more efficiently while simultaneously improving quality. This new technology from B&R features independent shuttles moved by permanent magnets along a long-stator linear motor track. Product movements can be configured individually, including variable speed and acceleration as well as batch grouping and ungrouping. The dramatic increase in processing speed makes your line more productive.

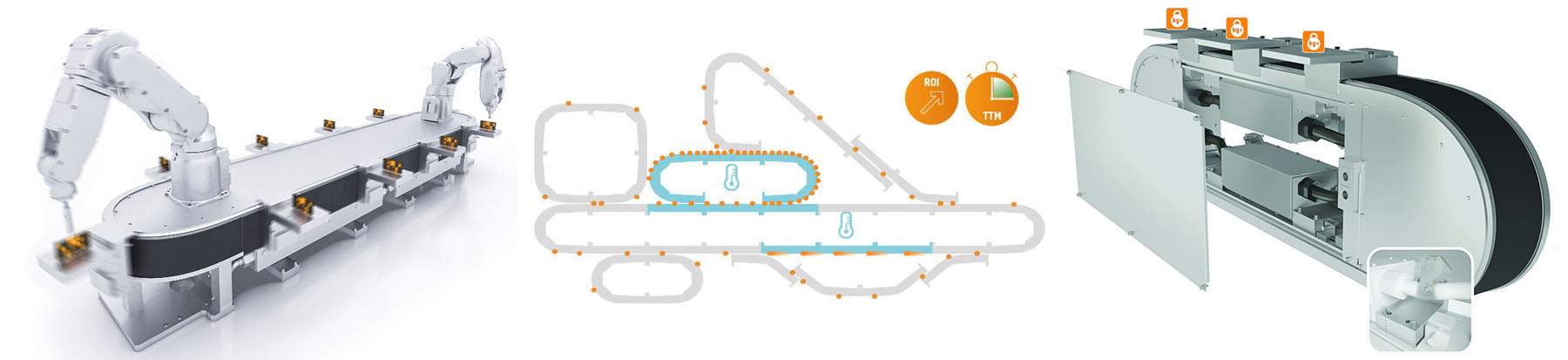

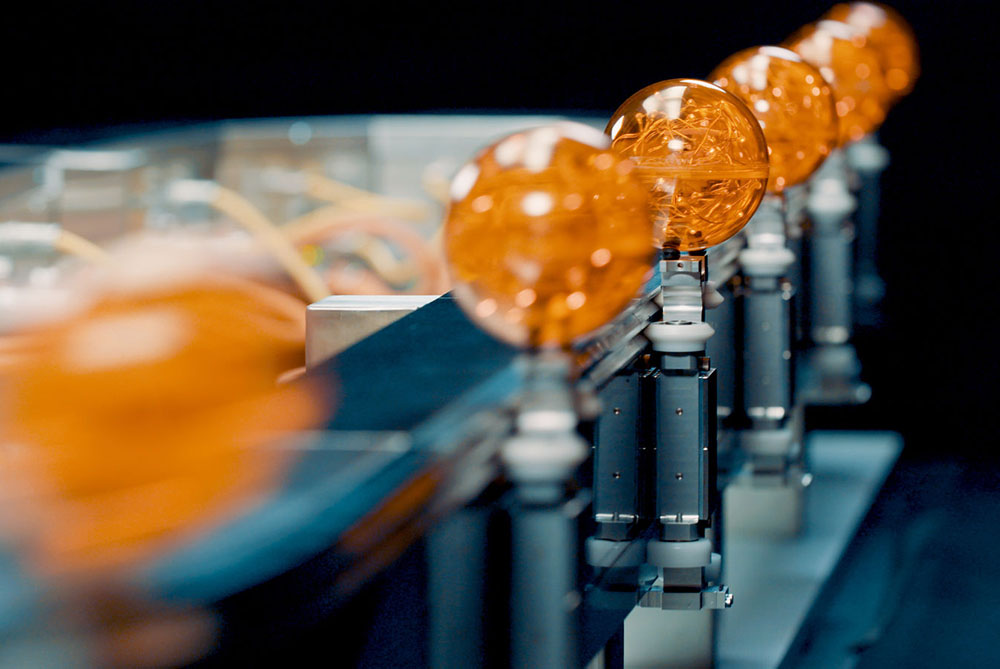

ACOPOStrak

ACOPOStrak is a revolution in adaptive manufacturing. This highly flexible transport system extends the economy of mass production down to batches of one. Parts and products are transported quickly and flexibly from processing station to processing station on independently controlled shuttles.

The unique design of ACOPOStrak delivers decisive technological advantages for adaptive, connected manufacturing. Produce small batches efficiently and benefit from the higher margins of personalized products

PLC Systems

High-speed precision of open and closed loop control for machines and systems – at an attractive price. B&R eliminates this seeming contradiction with the high degree of scalability of their control systems. This makes it possible for B&R to cover all requirements with a single platform – from the smallest controllers all the way up to CNC, robotics and process control applications. What’s more, this platform can be programmed and configured – regardless of the hardware being used – with Automation Studio. This compatibility reduces development costs while at the same time protecting investments made throughout the entire life cycle of the machine.

Vision Systems

With the world’s first machine vision solution to be seamlessly incorporated in the automation system, B&R takes integrated machine vision to a whole new level. The cameras, intelligent image processing algorithms and innovative lighting portfolio are an integral part of the B&R control system.

At the heart of B&R’s vision solution is a broad selection of intelligent camera technology. Options at the lower end will replace simple machine vision sensors, while the top of the range will harness the full potential of high-end smart cameras. For the entire portfolio of cameras, there are easy-to-configure machine vision functions for creating applications with minimal programming.

I/O Systems

B&R I/O systems are versatile and easy to use. With IP20 and IP67 protection, this is true in any combination, both inside and outside the control cabinet. And they also support all standard fieldbus systems. Complete flexibility regarding topology makes it possible for the I/O system to be optimally adapted to the machine. Standard I/O can be mixed with safe I/O, and decentralized intelligence is embedded in the I/O system so that things like condition monitoring can be easily implemented.

Safety Technology

Safety shutdowns do not always have to involve a full machine stop. Smart, safe reactions to various situations provide safety without having to stop the production process. Intelligent, decentralized and integrated safety technology from B&R with extremely short response times opens up an entirely new range of safety concepts for machines and systems. The full selection of machine options, the philosophy of programming instead of hardwiring, safe service and diagnostics and system-wide safe communication all come together to optimize both the flexibility and availability of machines and systems.

What We Offer.

Our Skills.

Concepts and Design

Work with our talented mechanical, electrical and controls engineers to develop your concepts from napkin sketch to feasible model. Once solidified, our designers will work to handle the details so you don’t.

Fabrication and Assembly

To control project costs and control quality, we fabricate, machine and assemble within our manufacturing area. Our engineers and designers continue to interact with our manufacturing team to assure the build is in line with customer expectations.

Installation and Commissioning

Our field service technicians will work with your manufacturing and production teams for a fluid installation and introduction of your new machine. The FAT process ensures satisfaction.

Project Management and Service

Non-tangible services often make or break a project. Our project leaders will continually keep you involved, and we stand behind our work, even after machine deployment.